The Center for Friction Stir Processing

From Center for Friction Stir Processing Guide

Contents |

The Center for Friction Stir Processing

“The National Science Foundation Industry/University Cooperative Research Center (I/UCRC) program develops long-term partnerships among industry, academe, and government. The centers are catalyzed by a small investment from the National Science Foundation (NSF) and are primarily supported by industry center members, with NSF taking a supporting role in their development and evolution. Each center is established to conduct research that is of interest to both the industry and the center. An I/UCRC contributes to the Nation's research infrastructure base and enhances the intellectual capacity of the engineering and science workforce through the integration of research and education.” [NSF Program Solicitation NSF 01-116]

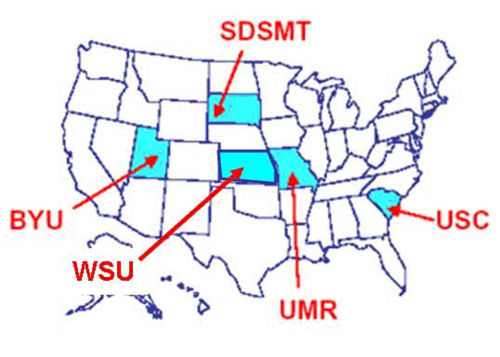

The Center for Friction Stir Processing (CFSP) is a multi-university Industry/University Collaborative Research Center (I/UCRC ) established in 2004 with a collaborative research partnership between the South Dakota School of Mines and Technology (SDSMT), University of South Carolina (USC), and the Brigham Young University (BYU). The Missouri University of Science and Technology (MUST, formerly UMR) was added as a university site in 2005 and Wichita State University (WSU) was added in 2007. Over 25 industry and government sponsors from five countries represent the current membership and provide funding for the research programs.

Gray and Walters have detailed the functional requirements of successful single and multi-university I/UCRC and make specific recommendations for center policies, procedures and practices (P3) which have shown proven results. In implementing these methods of Gray and Walters, the CFSP recognized several unique challenges to ensure meeting the administrative and management needs of the university sites, industrial sponsors, and the NSF.

To address these, a series of formal management tools have been instituted at the CFSP. Collectively, these are referred to as the Center Policies, Procedures, and Practices (P3). While the (P3) has shown to provide an effective management strategy for a multi-university I/UCRC, the CFSP is continually implementing improvements to incorporate more “Paperless Management” tools.

Gray and Walters state that a successful I/UCRC must first establish a vision; a mission statement; and, a list of objectives. The vision is the statement of purpose for the center – its reason for being, and how it hopes to impact the future.

“The vision, an idea of a possible future to achieve, is probably the most important ingredient in a successful strategy” [Gray and Walters, pg. 119]

The mission statement defines the goals for the center in broad terms. Gray and Walters note that the mission statement should contain four elements: who, what, means, and participants. The objectives are process-oriented and measurable, defining how the center will achieve the goals set forth in the mission statement.

For the CFSP, the defining statements about the center were developed collectively with the university site partners of the center. During the planning grant phase of the program, a meeting of over 30 prospective industrial members representing the leading industrial researchers in the FSP field was convened to define an initial listing of focused research topics. These topics represent the industry perceived gaps in the science and technology acting as barriers to more extensive industrial application of the technology. To define a comprehensive vision, mission, and objectives, the partner universities and potential industrial partners were identified very early in the planning grant process.

Although the vision statement; mission statement; and, a list of research objectives form the foundation of the center, they are not static and should be reviewed and revised by the Site Universities and Industrial Advisory Board (IAB) as the technology advances and the industrial membership needs change.

CFSP Vision

The Center for Friction Stir Processing (CFSP) vision is to provide the forum for industry/university cooperative research on the further development, validation, and industrial implementation of the emerging solid-state materials joining and processing technologies known as Friction Stir Welding (FSW) and Friction Stir Processing (FSP).

CFSP I/UCRC Mission Statement

The Mission of the NSF Center for Friction Stir Processing is:

- To advance, develop and promote research into the principles and technology of Friction Stir Processing science and engineering through research, development, education, and technology exchange among academic, industry, and government entities;

- To increase the quantity and quality of the professionals prepared to work in the area;

- To involve the faculty of the University(s) in research in areas of common interest to Sponsors and the University(s);

- To perform research that will allow global Friction Stir Processing facilities to be competitive in the world economy

CFSP Research Objectives

The overall objective of the Center is to develop and deliver relevant scientific knowledge that will help its industrial members with future challenges. Center programs are designed to complement the members’ in-house research and development in the area of friction stir processing by bringing together theoretical, experimental and application experts from industry and academia. The specific objectives focused on the following:

- Friction Stir Joining: Process optimization (parameters, pin tool materials, pin tool designs); process modeling (thermal, forces, metal flow, residual stress, distortion, microstructure evolution); microstructural characterizations; property characterizations (tensile, fatigue, fracture, creep, corrosion); nondestructive evaluations; new alloy development.

- Friction Stir Microstructural Modification: Induced superplasticity; grain refinement; sub-micron and nano particle injection; defect removal.

- Friction Stir Post–Processing: Heat treatment; forming (stretch, spin, age, and creep); machining; finishing.

- Friction Stir Structural Designs and Applications: replacement of fusion welds and rivets; static and dynamic response of structures; efficient design and analysis methodologies.

- Friction Stir Intelligent Controllers and Efficient Tooling: Process sensors; logic-based controllers; reconfigurable tooling.

- Friction Stir Cost Benefits Analysis: Business case development and environmental impact assessments.

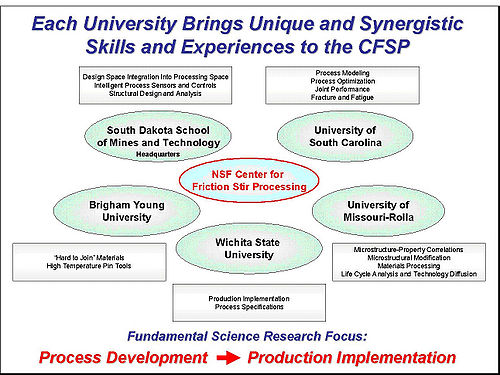

During the Planning Grant process of the CFSP, each potential industry sponsor identified focused research directions for the center that fit into their research resources. The university members then discussed their capabilities – equipment, availability of faculty with desired expertise, external relationships that could be explored – and the group found the optimal match between research initiatives and university capabilities at each site. Programs were then developed along the lines of the identified focused research areas at each site.

CFSP Policies Procedures and Practices (P3)

The following paragraphs outline the operating policies, procedures, and practices (P3) for the Center for Friction Stir Processing I/UCRC. They are coordinated and finalized between the participating universities during the planning phase of the program. Development of P3 follows those recommended by Gray and Walters with inputs from the CFSP Industrial Advisory Board (IAB) and from other sources. The CFSP Center Director may amend these P3 upon recommendation of the IAB, participating university faculty, or university administration. Approval of all policies and procedures are obtained from the appropriate Dean (or Provost) at the participating universities in accordance with the specific site university policies and procedures.

Membership Policy

Membership shall be open to all corporations, foundations, government agencies and/or other entities who: (1) own FSP facilities in the United States or who (2) directly contribute to support FSP research to make such facilities more efficient and competitive and or who (3) provide FSP products or services useful in FSP. Each Sponsor shall execute and agree to be bound by the terms of a Sponsor's Agreement and the policies and procedures set forth therein.

The membership fee for a Sponsor shall be $35,000 initially and annually. The initial membership term for a Sponsor shall be three years, contingent on availability of sponsor internal funding; thereafter the term shall be yearly subject to a notice of withdrawal of not less than six months. Payment of the membership fee may be made annually, semiannually or quarterly.

Industrial Advisory Board Policy

Each Sponsor shall have the right to designate a representative to be a member of the Industrial Advisory Board. The Industrial Advisory Board shall advise the Center Director and Site Directors regarding (a) research projects to be conducted under the university auspices, (b) the allocation of resources to such projects, and (c) the policies and procedures of the Center. The Industrial Advisory Board will meet at the call of the Center Director, normally twice each year.

Selection of Research Projects Policy

From time to time, the Center Director, Site Directors (Principal Investigator) and Industrial Advisory Board will prepare a list of potential research projects to be performed under the auspices of the Center. Thereafter, the Center will submit to University(s) faculty member’s requests for proposals setting forth all appropriate information related to the proposed research projects. Special emphasis will be placed on ensuring that faculty collaboration between multiple university sites is encouraged during the proposal preparation phase.

Upon receipt of all proposals from the faculty, the Industrial Advisory Board, Center Director, and Site Directors will decide which proposals will be funded and which university will be the principal site for the project. Each member of the Industrial Advisory Board having one vote for each project to be considered, subject, however, to the right of each site principal investigator to allocate up to one-third of the participating University funds budgeted for research to projects selected by the principal investigator and the participating University.

Project Investigators Policy

If the Center decides to support a research project, the faculty member(s) who submitted the chosen proposal for such project will be the Project Investigator and will assume the overall responsibility for managing the project. This responsibility will include:

- Organizing and conducting the research project.

- Selecting and supervising the appropriate research associates, graduate students, and technicians to conduct the research.

- Preparing and controlling the project budget.

- Periodically preparing semiannual and annual reports and, as appropriate final reports and external publications of the research findings.

- Organizing and participating in semiannual research review meetings with the Site Industrial Advisory Board and appropriate Technical Representatives to report on progress of the research.

From time to time, the Center Director, Site Director, and Project Investigators of each University will meet with each Industrial Sponsor to review the progress made in the research being conducted.

Regular Reports Policy

Written semiannual reports and more detailed annual reports documenting and summarizing the technical progress of individual research projects will be prepared by the applicable Project Investigators. The Site Director will forward these reports to the Center Director. The contents of these reports may include review articles and bibliography suitable for submission to journals. Oral presentations will be given to the members of the Industrial Advisory Board at the semiannual meetings. The annual Center Report shall also include a description of future research initiatives.

At the completion of each research initiative, each Project Investigator shall prepare a final report completely documenting the goals, objectives, approach, and conclusions of the project. Recommendations for future research initiatives shall be included. The Site Director will forward these final reports to the Center Director. Copies of all semiannual, annual, and final reports shall be forwarded to the Center Director for record retention.

Each year, the Center Director shall prepare a Center Annual Members Report summarizing the research activities of each of the Site Universities. Copies of the I/UCRC Annual Members Report shall be distributed to all sponsors. A bibliography of all site annual reports and center publications shall be provided to all sponsors in the Center Annual Members Report. This annual report shall also include a description of upcoming and proposed research initiatives of the CFSP.

Publication Policy

At any time a Project Investigator may request permission to publish information presented in semiannual, annual, or final reports or arising out of or resulting from research projects. To receive permission, the Project Investigator shall submit to the participating university Site Director the document to be published in substantially the form in which the Project Investigator will seek publication. Publication approval shall be withheld until publication approval is received in accordance with the procedures outlined in the CFSP Membership Agreement (Appendix A).

Patent Policy

All inventions or discoveries first conceived or reduced to practice in the course of research conducted under the auspices of the CFSP shall have the title vested in the Site University, which was the principal site. Multiple site projects shall have the title vested equally in each participating site.

Any invention or discovery which was supported, in whole or in part, by the National Science Foundation or other government agency shall be subject to the terms and conditions of the agreement by which such federal or state funds were used in the development of the invention or discovery. The CFSP Membership Agreement further defines the patent policy (Appendix A).

Termination of Research Policy

The CFSP Membership Agreement defines the Termination of Research policy (Appendix A).

Center Structure

Overall Center Structure

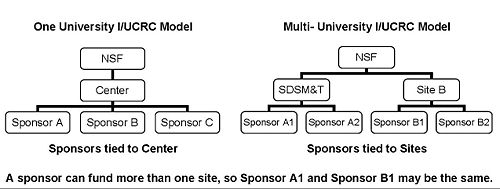

There are several possible models for overall structure of an I/UCRC. One model is for NSF and industrial sponsors to fund the center as a whole. The model chosen by the CFSP is for sponsors and NSF to fund particular sites directly. This way, a sponsor can attach itself more closely to particular projects at a particular site. A sponsor does have the option of having multiple memberships at several sites if it is willing to provide funding for each membership.

This direct funding of sites by both NSF and the industrial members does have a negative side – if communications, collaborations and coordination between the university sites are not emphasized to the maximum levels, the potential exists for one site to become an “island” and drift away from the overall vision, mission and objectives of the Center. It is the challenge of the Center Director to ensure that this does not happen.

The division of focused research directions among the participating universities prevents redundant efforts as well as reducing the number of communication paths required to perform the work. Note that a research thread may be divided between several universities, but, to the extent possible, project leadership is confined to a single site.

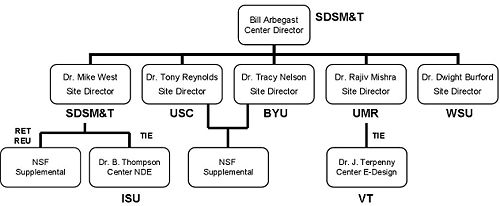

University Partner Structure

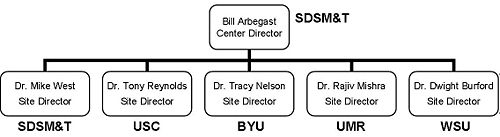

The center is composed of universities and industry partners distributed across the world. From the university perspective, there at five participants: South Dakota School of Mines and Technology (SDSMT), the Missouri University of Science and Technology (MUST), the University of South Carolina (USC), Brigham Young University (BYU), and Wichita State University (WSU). Each is an equal partner with a Site Director responsible for center activities.

The CFSP Center Director is located at SDSMT. Each of the Site Directors is responsible for the operation of the center at their respective university. The Center Director is responsible for overall performance of the center.

Collaborations between other NSF I/UCRC Centers and CFSP participating university sites are possible through Supplemental NSF TIE programs and REU and RET funding define additional research opportunities related to friction stir processing (Section 3.6). Typically, a site university has CFSP IAB approved research projects plus additional friction stir sponsored research programs outside of the purview of the center. The CFSP Site universities are encouraged to collaborate on proposals and research opportunities from these other industry and government sources.

Other Participants: NSF and Industry

Other participants in the I/UCRC process include industrial members and the National Science Foundation. The I/UCRC program was created by the NSF to stimulate research in emerging technologies critical to national economic competitiveness. NSF provides oversight of the CFSP through the NSF I/UCRC program office (http://www.nsf.gov/eng/iip/iucrc/). The University of Central Florida has “virtually cloned” the corporate memory of the I/UCRC program office with “Ask Alex” (http://isl.ucf.edu/AskAlex/) where questions can be asked of the NSF I/UCRC program founder, Alex Schwarzkopf.

A CFSP Center Evaluator (Mr. Ron Beck) provides assistance to the center and to provide additional program oversight. The Center evaluator’s annual salary is paid equally by each participating university site. To minimize billing issues, one billing is made to the Lead CFSP University site (SDSMT) and funding is invoiced and transferred from the participating university sites to cover their portion of the salary. The North Carolina State University maintains an I/UCRC Center Evaluators website (http://www.ncsu.edu/iucrc/) where the evaluator’s roles and responsibilities are described and improvements in the NSF I/UCRC program best practices are posted and discussed.

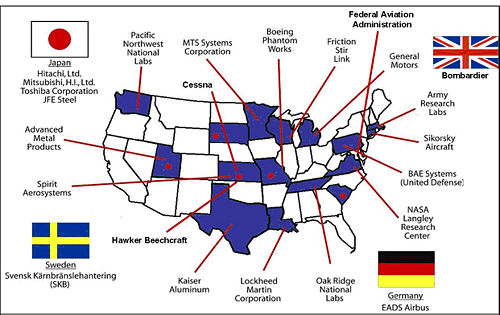

The global CFSP Industry membership is listed on the CFSP website (http://cfsp.sdsmt.edu/). As of the writing of this document, they are Army Research Laboratory, Boeing Phantom Works, BAE Systems (UDLP), MTS Systems Corporation, Pacific NW National Labs, Sikorsky Aircraft Systems, EADS Airbus, Kaiser Aluminum, Lockheed Martin Corp., NASA Langley Res. Center, Spirit Aero Systems, Advanced Metals Prod., Hitachi, Ltd., JFE Steel, Mitsubishi, H.I., Ltd., Swedish Nuclear Fuel & Waste, Management Co, Friction Stir Link, General Motors, Bombardier, Cessna, FAA, and Hawker Beechcraft. Members come from the USA, Japan, Sweden, United Kingdom, and Germany.

The CFSP Membership Agreement (Appendix A) defines that there will be an Industrial Advisory Board (IAB) for the Center composed of one representative of each corporate sponsor. The CFSP Bylaws (Appendix B) clarify this by saying that if a company has paid for more than one membership, they have one vote on the IAB for each paid membership. Companies can send more people to the meetings than they have memberships, but the number of memberships limits the number of votes that can be cast by the representatives of the company.

There is an IAB Chairman who is elected by the IAB for a term of not more than two years. The bylaws give the IAB Chair two duties. First, is to work with the Center Director and Site Directors to establish the schedule of activities and meetings for the Center as well as the agenda for the meetings. Also, the IAB Chair can speak for the IAB, working with the Center Director and Site Directors, to approve an interim research program funded by a new corporate sponsor of the center. Otherwise, funding from a new sponsor must be applied to a previously approved project. The IAB Chair also serves the usual role of a chair of a board, acting as the point of contact and running meetings.

All sponsors participate in the strategic planning of the Center. The IAB assists the participating faculty in identifying pre-competitive, generic, industry-related, research problems in friction stir welding and processing; recommend research projects for future work; assist in identifying appropriate industrial internship opportunities for graduate students and postdoctoral students; assist the Center Director and Site Directors in identifying new sponsors; review the research and educational accomplishments of the Center; and recommend restructuring and/or redirecting of on-going programs to meet IAB needs and concerns. ((Appendix B) – Bylaws: 4.3)

The CFSP Center Director is responsible for all Center activities and reports directly to the Vice President for Research at the South Dakota School of Mines and Technology and is responsible to the IAB. The Site Directors at the lead and site universities are responsible for Center activities at their university and report directly to their respective university administrators and to the Center Director.

The Site Directors also provide liaison between the Center and the appropriate academic departments of the partner universities. Site Principal Investigators manage specific research projects funded by the Center and report directly to the appropriate Site Director, the appropriate university administrators, and to the sponsors supporting the project. ((Appendix B) – Bylaws: 4.4 - 4.6)

The CFSP has formed an ad-hoc multi-university administrative oversight and policy committee consisting of the Vice President or Provost of Research (or his/her designee) at each university to resolve any and all Center administrative issues, including review of academic standards, recruitment strategies, retention issues, funding issues, space requirements, and equipment requirements related to the Center. Additionally, the committee ensures that the lead university and each participating university have provided a reasonable level of clerical and accounting support staff for Center operations. A major role of the committee is to ensure faculty recognition for participation in the Center in tenure and promotion decisions, and ensure that the research is appropriate for graduate education. This committee is convened at the request of the CFSP Center Director to resolve center related issues. ((Appendix B) – Bylaws: 4.9 - 4.10)

CFSP Partner Site Outside Research – The SDSMT AMP Center

A university participating in the CFSP I/UCRC retains the right to pursue contracts related to friction stir processing which are outside of the purview of the center. All of the universities in the CFSP have such outside activities. Note that there is a “handshake” agreement between university Site Directors that they will not compete for the same outside funding- but will pursue collaborative funding whenever possible.

At SDSMT, the Advanced Materials Processing Center (AMP) (http://ampcenter.sdsmt.edu/) is the local entity for friction stir processing activities. Colloquially, all friction stir processing activities are referred to as AMP, but the research and experiments conducted under AMP for non-CFSP members must be scrupulously separated from other center work products.

CFSP Industry sponsors expect their experiments, results, and ideas to be kept confidential and proprietary, and experiments run for AMP cannot be used for CFSP sponsors and vice versa. This sometimes means the same experiments must be run twice for different sponsors because to do otherwise would be to share results between competing industry sponsors. This distinction is critical when designing policies, procedures, practices, and automated management tools for the center.

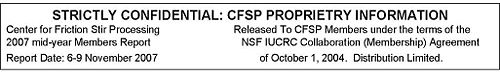

All CFSP experimental data, reports, posters, and presentations contain a proprietary information banner to identify and restrict distribution. Web and database security is also a prime consideration to prevent non-center members from viewing test results paid for by CFSP members.

Electronic Resources

A multi-university I/UCRC faces significant communication challenges. When managing the center, methods of communicating and disseminating information, along with the protocols for each, need to be established. Two tools that are indispensable are an interactive web site and a shared database.

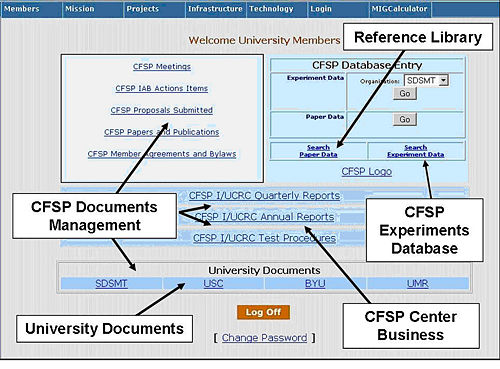

Websites

The official CFSP website (http://cfsp.sdsmt.edu/ ) is the primary program management and communications tool used and described in detail in subsequent Sections of this case study. This website is a secure website available to university sites and IAB members through password controlled access. However, a few design considerations are generally applicable to any I/UCRC.

- Marketing materials and general information should be available to non-center members to encourage new sponsors to join the center. The educational mission of a center also dictates dissemination of information about the research and technologies developed by the center to as wide an audience as possible.

- Proprietary materials and private communications need to be behind the password-protected Section of the website. Multiple layers of access are desirable if the website is dynamic, that is, if content can be edited by multiple individuals with the proper authorization.

- Restricting editing privileges to a system administrator creates delays in the dissemination of information. At least one individual for each site should have the ability to upload documents, fix errors in web pages, and post news items.

- A communication mechanism should be set up to automatically notify interested parties when a document is added to the web site. For example, when a Quarterly Report is added, the industry sponsor would be automatically notified via email or RSS feed or through a messaging system. Although reports posted to the web site often require prior approval by the Site Director, automatic notification that the report was actually posted is desirable. Tools that prepare summaries of posted reports and missing reports will also facilitate student oversight.

- Meeting information, action items, reports, proposals, publications generated by center members, and other administrative documents are logical items to distribute via the web. Pages which display these items can be dynamically generated to reduce administrative overhead for web maintenance.

A dynamic website is most often implemented by storing the page entries in a database. This can be a simple engine or even done with files. The main page of the CFSP website contains the marketing information of Center mission, vision, objectives overview, university affiliates and sponsor information and is available for review by non-CFSP members. A secure login portal is provided for both CFSP member and university sites to gain access to the proprietary CFSP documents and reports, and, the comprehensive CFSP database.

Databases

The ability to store, share, retrieve, and mine experimental data is crucial to fully utilizing the work products of all sites. Design of the database should occur very early in the center planning process (call your computer science department as soon as possible) for two important reasons: (1) it is often difficult to adjust the table structures once population of the database begins and (2) as noted above, each site may have independent research which may be, or already is, stored in a database. Coalescing distributed, heterogeneous databases is a non-trivial task which may be avoided with advanced planning.

Typically, each site would host a database for its non-center work and also contribute to the central CFSP database. To reduce the complexity for students, a common data entry interface is desirable. It is also optimal for all sites to select a common database engine.

The first task is to decide the information to be stored in the joint database, taking into account that some fields may exist solely to facilitate the use of a common interface for local (non-center) experiments and center experiments. Database security must be part of the initial design. This includes preventing access to the data by non-members, segregating center from non-center data if the same database is used for both, and restricting editing privileges.

The database is useful for building a reference library for center members. The reference library (Section 3.4) is essentially a distillation of papers read by students, faculty, and other center members to facilitate scholarly activity. Summary information stored in a database, coupled with a keyword search, provides a powerful mechanism for locating reference materials.

Document Management Systems

In addition to a mechanism for storing experimental data, a Center may find it useful to design a document management system for tracking work products. The final form of Center related documents (Annual Members Reports, NSF Annual Reports, LIFE Form Reports, Center Publications, IAB Presentations and Posters, Members Agreement, By-Laws, and Center Action Items) is posted on the website and available for members to download.

In addition, the AMP Center has developed PaDMS, the Paperless Data Management System, for controlling documents related to individual research projects and tasks. A unique project identifier using the CFSP naming conventions (Section 3.11) is assigned to each research project and each experiment is conducted under a formal work order control number (Section 3.8.4) and is the primary key that ties all related documents together.

The work order also contains the project designation which is used as a reference into the experimental data database. The student assigned to perform each experiment under the work order is required to prepare a laboratory report in a standard format to describe the results of the experiment before approval and closure of the experimental task is authorized by the Project Investigator or Site Director. Use of PaDMS is described in Section 3.

Budgets and MIPR

Each university site has unique budgetary procedures to control funding from NSF and the Center Sponsors. The CFSP IAB has requested that budgetary information related to each project be included in all project reviews. To accommodate this, a simple “division of efforts” approach has been instituted at each site.

Under this method, the Site Director has the option of defining and distributing how much of the sponsors membership fees are allocated for each project. Likewise, distribution and control of the NSF funding, including the award and Military Interdepartmental Purchase Request (MIPR), is allocated at the discretion of the Site Director. At the Annual IAB meeting, these distributions are presented to the board and are subject to their approval.

At the SDSMT site, individual top level research project topics approved by the IAB are identified and the budgets are monitored individually by the university accounting system with separate accounting codes. Within each project, subtask budgets are allocated at the discretion of the Site Director and are not monitored and controlled to this level.

At other CFSP university sites, this level of control may not be applied with all members funding placed into one university accounting code and allocation of funding is controlled by the Site Director. The IAB have found both of these systems acceptable and generally is satisfied when knowing the top level of funding allocated to each project task and subtask.

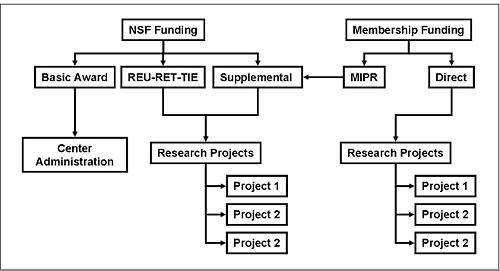

Funding for the center can come from many sources. Under the basic I/UCRC award from NSF, funding for center administration is received separately for the center lead institution and each university partner site. Additionally, each site may receive REU, RET, TIE and Supplemental funding which is added to the basic award by NSF (Section 3.6). These funds are, however, to be used for center research and not center management.

At the SDSMT, the university accounting system is used to separate these funds using unique account codes for each REU, RET, TIE, and supplemental received rather than inclusion into the accounting code for administration. This allows tracking and reporting of these NSF funds to the IAB as they are expended for each project.

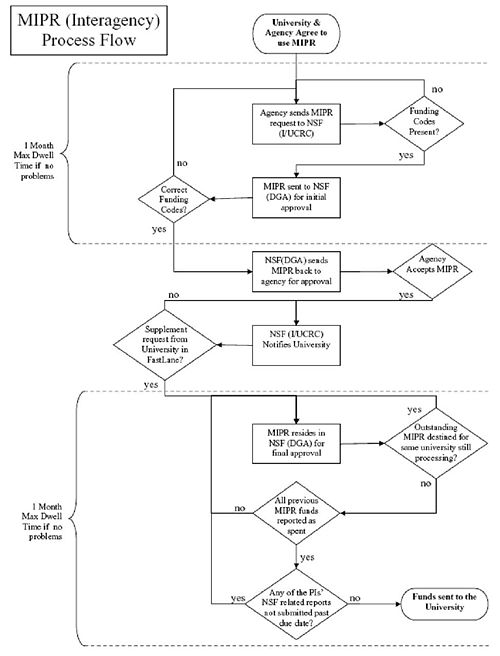

Likewise, direct membership funding is split and distributed into unique accounting codes for each project currently being conducted. Membership fees from government entities (DOD, DOE, and NASA) are typically transferred to the center using DD Form 448 - Military Interdepartmental Purchase Request (MIPR). Under this process, the government member transfers its membership fee to NSF which in turn sends it to the appropriate university site as supplement to the basic award. Special rules apply to MIPR funds transferred to the center in this manner.

First, NSF may “tax” this transfer at a 3% level which reduces the total funding to the center. It is often requesteded, therefore, that the government member increase the amount transferred to NSF by this amount so that the money flowing down to the center is compliant with the total membership fee. Secondly, MIPR monies must be tracked separately to ensure that they are spent during the fiscal year it was awarded. Failure to ensure that this money is spent each year will delay funding of subsequent year MIPR funding. At the SDSMT, a unique university accounting code is assigned to all incoming MIPR monies to track and control the expenditures.